Equipment Overview:

The micro-computer-controlled electro-hydraulic servo testing machine adopts a double space structure under the cylinder,Wherein: the stretching space is between the upper beam and the lower beam,The tensile test of the sample is mainly carried out.The space between the test bench and the lower beam is compressed,The test of compression, bending and shear of the sample can be realized,Both the stretching space and the compression space can be automatically adjusted by rotating the lead screw to drive the lower beam up and down。

The testing machine is mainly used for tensile, compression, bending, shearing and other tests of metal materials. Equipped with corresponding fixtures, it can be used for tensile, compression, bending, shearing, bending and other tests of other types of samples。

The closed-loop servo control system composed of electrical controller, servo valve, load sensor, displacement sensor, extensometer and computer can control the test process automatically and accurately, and measure test parameters such as test force, displacement and deformation automatically。

The testing machine can realize the test of equal rate loading, equal rate deformation and equal rate displacement, and can realize the control of force, deformation and displacement in one test, and the control can be smoothly converted between each control。

The test parameters can be automatically controlled and the test results obtained by computer acquisition and software processing。The test curve and test result are displayed in real time by the microcomputer screen, and the test report and test curve can be printed。

Meet the criteria:

1) GB/T 2611 "General Technical Requirements for Testing Machine"

2) GB/T 16826 "Electro-hydraulic Servo universal Testing Machine"

3) JJG 1063 "Electro-hydraulic Servo Universal Testing Machine"

4) GB/T 228.1 "Metal materials tensile test - Part 1: Test method at room temperature"

Technical parameters:

型号 | HUT106C |

Maximum test force | 1000kN |

Accuracy class | 0.5级 |

Relative error of test force indication value | ±0.5%以内 |

Test force measurement range | 1%-100% FS (full ungraded) |

Deformation measuring range | 1%-100%FS |

Relative error of deformation indication | ±0.5%以内 |

Deformation resolution | 1/500000FS |

Piston stroke | 250mm |

Maximum speed of piston rise | 0 to 90mm/min |

Maximum speed of piston descent | 310mm/min |

Number of columns | 6柱 |

Effective distance between columns | 450mm |

Maximum effective stretching space | 1000mm |

Maximum effective compressed space | 900mm |

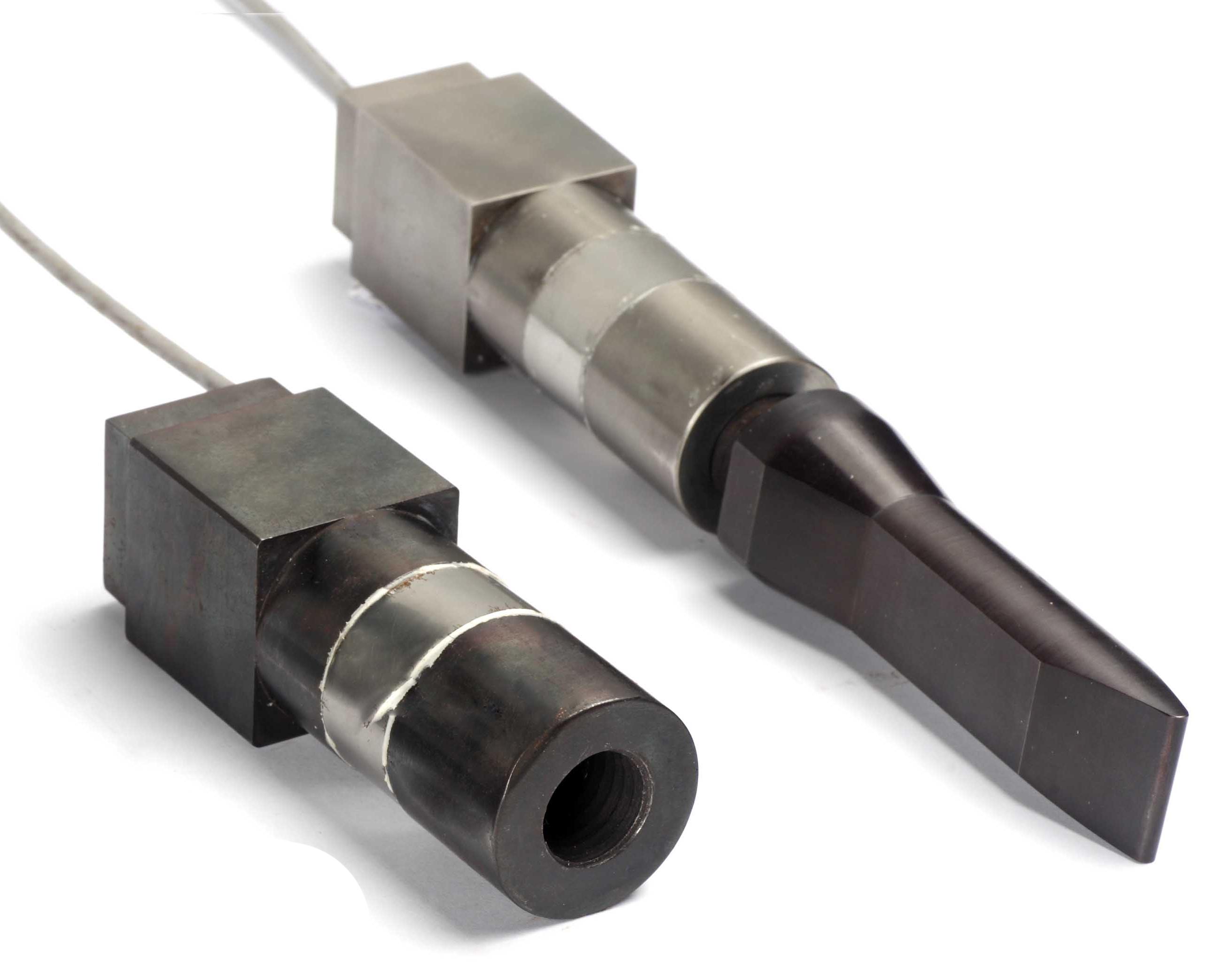

Circle specimen clamp range | Φ10 ~ Φ45mm |

Plate specimen clamping thickness range | 2~40mm |

Platen size | 200x200mm |

Main engine dimensions | 1020×670×3050mm |

Oil source dimensions | 1150×600×900mm |

电源 | AC 380V± 10%, 50Hz, 4kW |

Main engine weight | 4200kg |

The testing machine is mainly used for tensile steel strand, equipped with the corresponding fixture can be used for tensile, compression, bending, shearing, bending and other types of samples。